5a-faucet: A water saving innovation

with enhanced mobility

During my time at DG TAKANO, I had the privilege of contributing to the 5a-Faucet project, an exciting collaboration with the renowned industrial design firm Whipsaw. This project aimed to create an innovative, water-saving faucet with a user-focused design.

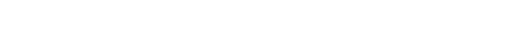

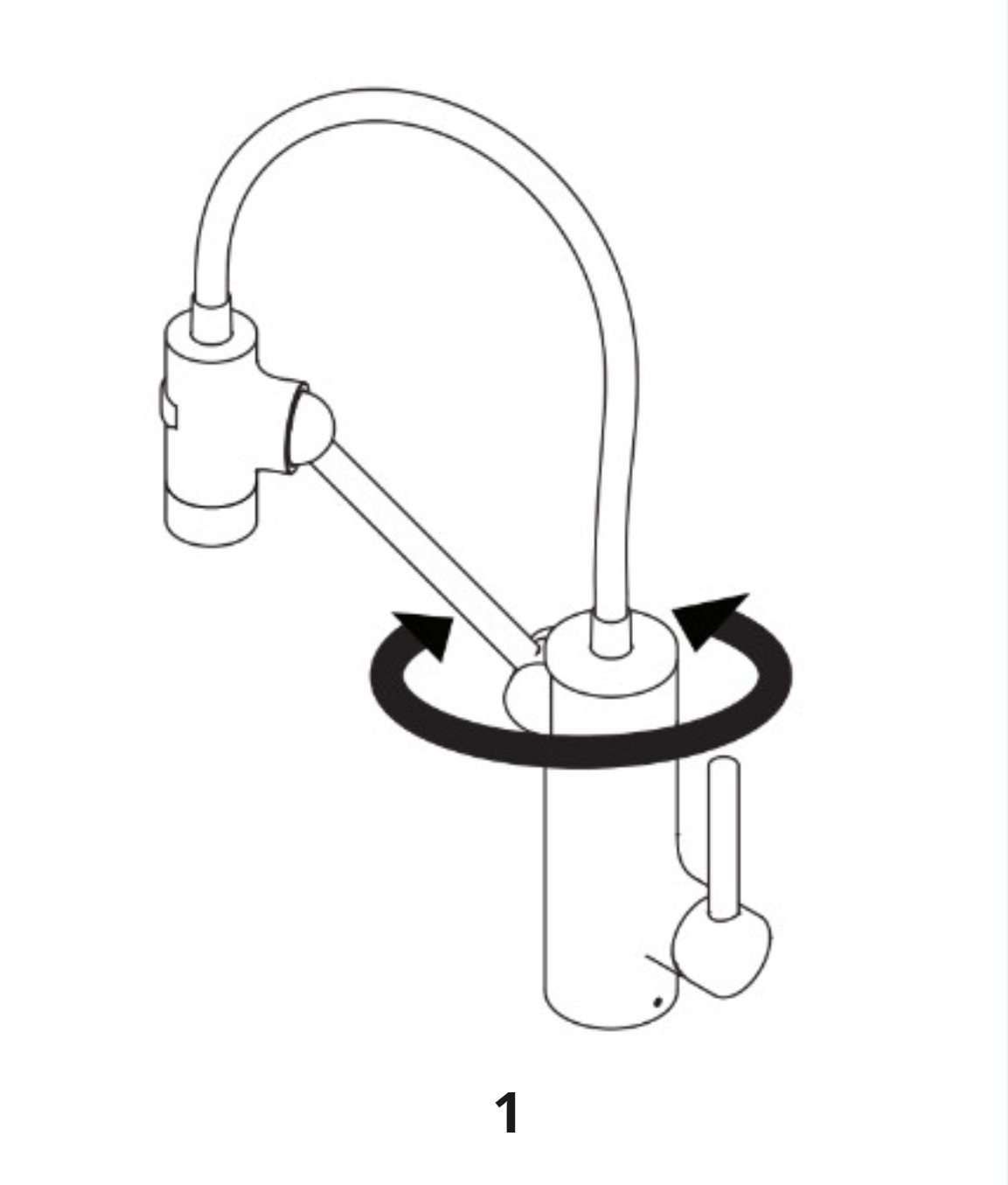

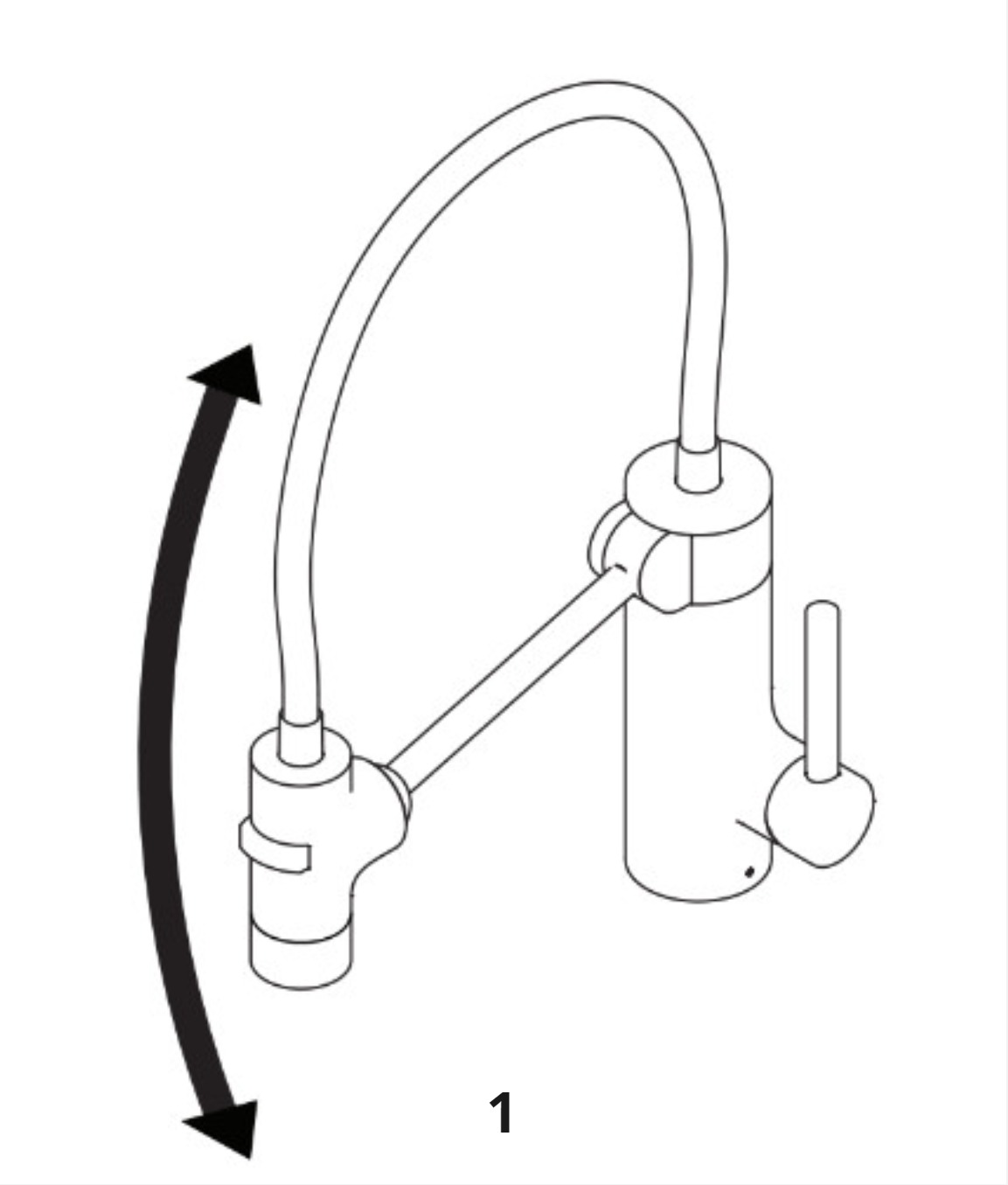

This faucet, named "5a" for the five degrees of freedom it offers, provides unparalleled spatial coverage, allowing the faucet-head, acting as the end-effector, to reach a broader operational area. This enhances usability and functionality, making it ideal for modern kitchen environment.

My primary role in the project was the design and development of the faucet-head, which incorporated DG Takano’s flagship Bubble90 Blue for pulsating flow. I focused on creating a unique aerated flow design, where water exits from the boundary of the faucet-head. This required careful regulation of the flow rate, pressure, and outlet shape to produce a stable, splash-free, and visually appealing flow. Achieving this involved many iterations. Unlike most faucets on the market, which use Neoperl aerators, we developed our own in-house aerator that integrates seamlessly with the Bubble90 and creates a striking conical flow.

The 5a-Faucet, with its multiple degrees of freedom and complex movements, presents numerous potential points of failure. To ensure reliability, I conducted extensive durability tests, simulating over 100,000 cycles of the faucet’s various movements. As demonstrated in the clips above, I designed automated testing jigs to replicate the motion of the arm, magnet docking ball joint, and multiple hinges integrated into the design. These tests were critical for assessing fatigue, wear, and long-term mechanical performance, ultimately ensuring the product’s robustness and durability.

More details about the product can be found on WHIPSAW's and DG Takano's websites.